Are you constantly battling against the relentless forces of corrosion in your industrial environment? Imagine a solution that not only withstands these harsh conditions but thrives in them. In places like Sydney where coastal elements can accelerate wear and tear, choosing the right FRP grating can be the difference between constant maintenance and long-lasting durability.

In this essential guide, we’ll explore how to choose the most effective, corrosion-resistant FRP grating for your needs. And remember, this is just the beginning – keep reading to learn the secrets to maximising the lifespan and efficiency of your industrial applications with Meshstore’s expertise.

What is FRP Grating

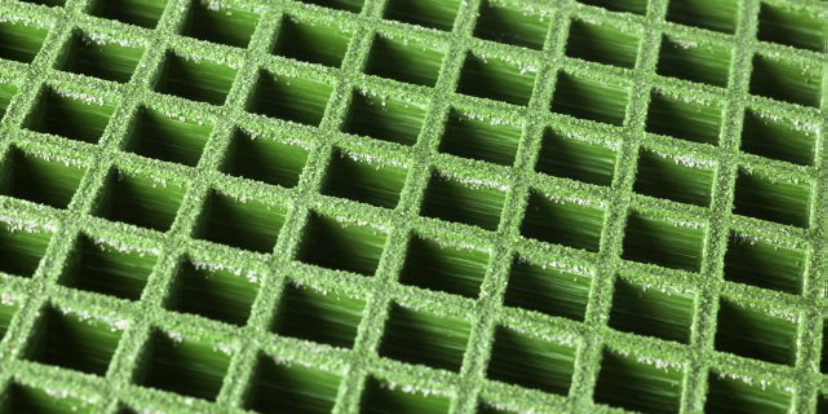

FRP grating is a composite made from fibre-reinforced plastic, boasting a unique combination of strength and corrosion resistance. It stands out as an ideal choice for areas prone to chemical exposure, moisture, and other corrosive elements. The inherent properties of FRP grating, such as its non-conductive nature and fire resistance, further amplify its suitability for challenging industrial settings.

Factors to Consider When Choosing FRP Grating

Environment Suitability: It’s essential to assess the specific environmental conditions where the FRP grating will be used. This includes considering factors such as the type and concentration of chemicals present, the range of moisture levels, and the extent of temperature variations. This assessment ensures that the chosen grating will perform optimally under your specific conditions.

Load-Bearing Capacity: The FRP grating you select must be capable of handling the weight and type of traffic it will encounter. This could range from light pedestrian traffic to heavy machinery, each demanding different strength and durability standards.

Slip Resistance: Safety is paramount, making slip resistance a critical factor. Opt for grating with a surface designed to prevent slips and falls, especially important in environments where surfaces are likely to be wet or oily.

UV Resistance: Prolonged exposure to sunlight can deteriorate many materials. Ensure that the FRP grating has UV-resistant properties to prevent weakening and colour fading over time.

Ease of Installation and Maintenance: A practical aspect to consider is the ease of installation and the level of maintenance required. Choosing FRP grating that is straightforward to install and demands minimal upkeep can significantly reduce long-term costs and downtime.

The Benefits of FRP Grating Sydney

Choosing FRP grating in Sydney offers significant advantages. The material’s inherent corrosion resistance is perfectly suited to the coastal and industrial environments common in the region. Furthermore, the lightweight yet robust nature of FRP grating makes it not only easy to handle and install but also ensures its durability and longevity in demanding conditions.

The Role of Fibre-Reinforced Plastic Grating in Industrial Applications

Fibre-reinforced plastic grating is exceptionally versatile, lending itself to a variety of industrial applications. Its use extends beyond just walkways and platforms to include drainage systems and protective linings. This versatility, coupled with its resistance to harsh conditions, ensures both longevity and safety in a broad range of industrial settings.

Choosing the Right Supplier

Selecting a reputable supplier like Meshstore is pivotal when sourcing FRP grating. With a comprehensive range of high-quality options tailored for diverse applications, their expertise and customer-centric approach ensure that you receive a product that aligns perfectly with your specific needs and environmental conditions.

Conclusion

It’s clear that the right selection of FRP grating is not just a choice – it’s a strategic investment in the longevity and safety of your industrial environment.

Once again here are the best tips for choosing corrosion-resistant FRP grating:

1. Check environmental compatibility.

2. Consider the weight it needs to support.

3. Look for slip resistance.

4. Ensure it’s UV-resistant.

5. Ease of installation and maintenance.

By keeping these simple tips in mind, you can choose the right FRP grating for your industrial needs, ensuring it lasts long and performs well in tough environments.

With our high-quality, corrosion-resistant FRP grating, specifically suited to the demanding Sydney environment and beyond, you’re not just purchasing a product – you’re securing peace of mind. You’re ensuring that your operations run smoothly and efficiently, day in and day out, with minimal disruption and maximum safety.

As you stand at this crossroads, consider the impact of your decision. Opting for the superior, durable solutions offered by Meshstore means choosing a path of resilience and reliability. It’s not just about meeting the immediate needs of your project; it’s about envisioning and securing a future where your industrial environment thrives under the most challenging conditions.

Don’t let another day pass with the weight of uncertainty on your shoulders. Embrace the change that Meshstore’s FRP grating brings. Visit us at meshstore.com.au and take the first step towards transforming your industrial landscape. Choose excellence.

Choose durability. Choose Meshstore – where your industrial needs are not just understood but anticipated and met with cutting-edge solutions.

Act now, and pave the way for a brighter, more secure industrial future.