Wire mesh is a favourite for projects of all sizes due to its versatility, durability and strength. But of the two most common mesh products – woven wire and welded wire – which is better for you?

Variations in the manufacturing processes mean each mesh type has distinct qualities, making them better suited for different applications.

Let’s have a look at the main differences between woven and welded wire mesh, and how this impacts their practical usage.

Woven wire mesh has a wide variety of applications.

How are they made?

1. Woven wire mesh:

This style of wire mesh is made by weaving the wire strands under and over each other, resulting in an interlocking sheet, with no need for further processing.

There are a variety of weave types when it comes to woven wire mesh, with each being suited to different applications. These include:

- Plain weave/square mesh – This is the most common, with the square shape of the mesh created by spacing the wires at equal distances in both directions.

- Rectangular mesh – Also known as broad/oblong mesh, this is often used for vibrating sieve screens.

- Dutch twilled weave – Here the horizontal (or weft) wires are forced together during the weave. This gives an especially smooth surface useful for filtering.

- Crimped screen – Often used for gates and fences, crimped wires are used both horizontally and vertically, creating a strong wire screen.

- Plain dutch weave – The weft wires are placed together as closely as possible, creating what is called a ‘Zero Mesh’. This weave is known for giving even openings and good flow rates.

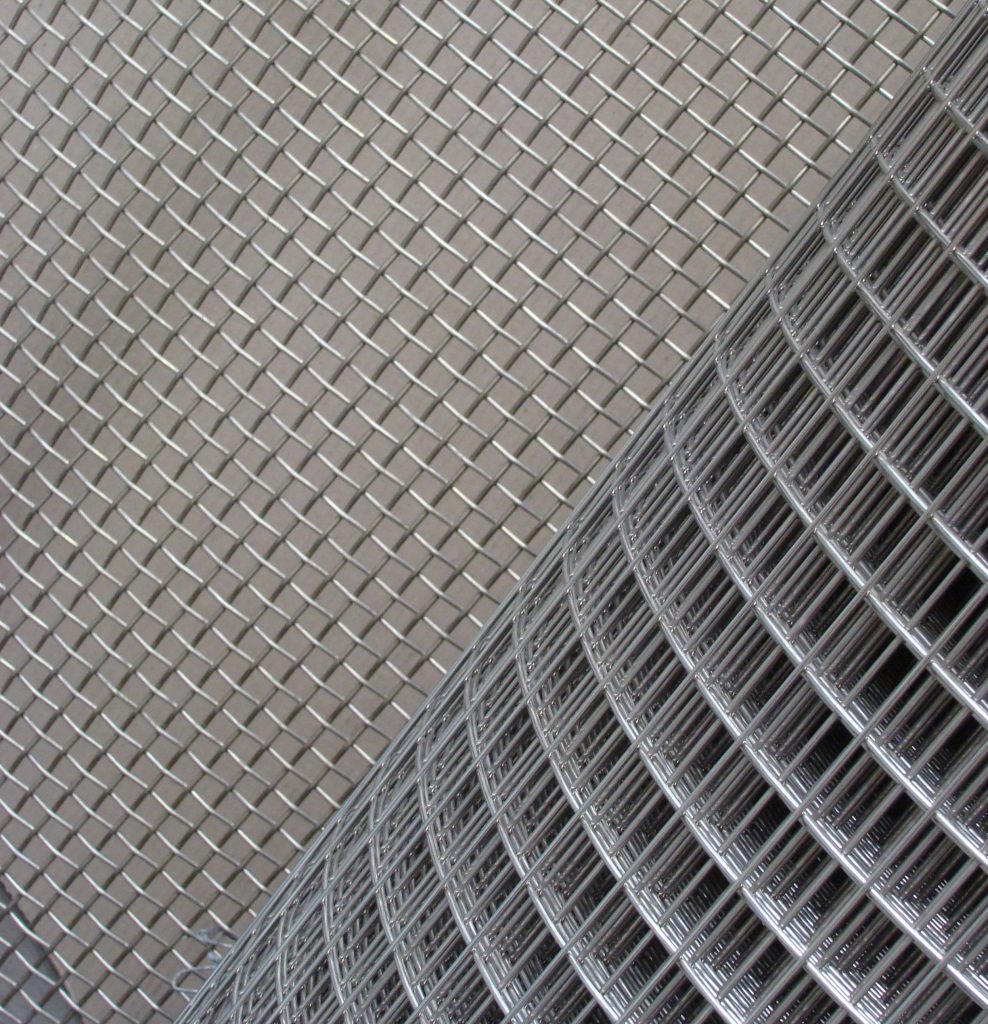

2. Welded wire mesh:

Also known as weld mesh, welded wire mesh involves the same practice of laying the wires over each other, but this time they’re spot welded into place at the intersecting junctions.

Again a square pattern is the most common result of the process, and the product usually comes as a mesh roll or as a sheet, depending on its weight.

Which is stronger?

Both woven and welded wire mesh are strong enough to be used in high load-bearing applications such as flooring. However, in a direct comparison, welded wire mesh comes out on top due to the way in which the overlapping wire joints are welded together.

The strength advantage that welded mesh has over woven mesh is one reason why it’s a favourite for use in security screening and building reinforcement. The result of this additional support is the ability to create uniform, and larger, opening sizes that remain rigid even under high strain.

Which is more flexible?

The lack of welding in the manufacture of woven wire mesh means that it takes the biscuit for flexibility over its welded cousin.

By weaving the wires over and under each other tension is created across the mesh. While this does give strength, it also allows for a degree of pliability making for a product that is able to bend without breaking.

As a result woven wire mesh is useful when a bit of give-and-take is desired. Examples include animal flooring, ventilation and bird aviary mesh.

Which is more cost effective?

Due to the extra work that goes into producing welded wire mesh, it tends to be a bit pricier.

However, the additional strength that results from welding the wire intersections together means it’s worth investing that bit more if your application is likely to put high strain on the mesh.

What materials can I choose from?

Both woven and welded wire mesh are available in a range of different metal substrates, and you should choose yours based on the use you have in mind.

- Brass mesh: Due to its relative lack of corrosion resistance, brass meshes are better for internal uses where aesthetic value is key.

- Stainless steel mesh: Stainless steel is also great to look at, but this product has the added benefit of being easy to clean and sterilise, and so works well in applications where hygiene is an important consideration.

As wire mesh is often employed in external settings, it’s important to know how your product will stand up to the test of the elements. Finishing techniques can add an extra layer of protection for mesh products, with galvanising being a popular option due to its cost effective and long lasting results.

With this information on woven and welded wire mesh, you should have a better idea of which is more suited to your project. To find out more about wire mesh get in touch with the team at Meshstore today